Most print on demand sellers never touch the products they sell. That's why quality control isn't optional; it's your brand's frontline defense.

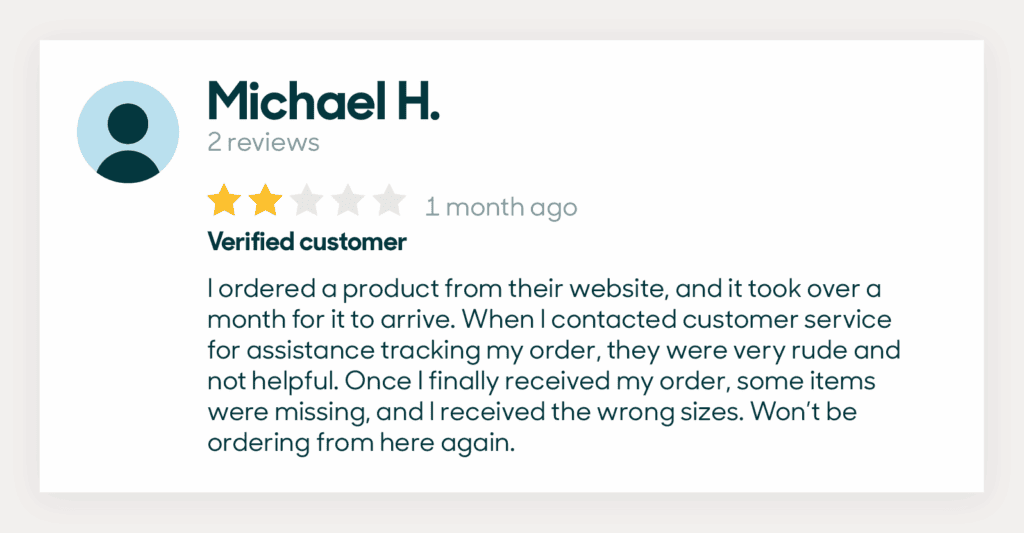

A poor print, faded design, or incorrect size can result in refunds, negative reviews, and lost loyalty.

That's why we created this article!

Whether you're launching your first product or scaling your top seller, these steps will help you avoid costly mistakes and build customer trust.

Quick Answer: How to ensure product quality in your print on demand store

Ensure product quality in your print on demand store by ordering samples, following supplier file specs, using consistent design templates, and reviewing print previews.

Monitor customer feedback, avoid low-resolution uploads, use golden samples as benchmarks, and maintain backup suppliers for your bestsellers to guarantee consistent results.

Here's what to do before you hit 'publish' on your next product!

Launch your print on demand store on Shopify

Free 3-day trial + $1/month for 3 months

- Plug in leading POD apps in a few clicks

- Sync designs and mockups straight into your storefront

- Focus on designs while Shopify handles checkout & payments

No card to start. Cancel anytime.

8 Proven ways to control quality in your print on demand store

Here's how to spot issues early, ship confidently, and keep customers returning:

1. Always order samples before listing new products

Mockups simulate design visuals but often fail to reflect the real-world print quality accurately.

Order at least three samples for each major variation, including different suppliers, colors, and sizes.

This helps you check print quality, sizing, fabric feel, and color accuracy across batches.

Printful and Printify warn that skipping samples leads to surprises and support issues.

Without samples, you can't create realistic photos or confidently answer customer questions.

Investing in samples upfront helps you avoid costly mistakes later.

Related article: Printful vs. Printify: Plans, Pricing, and Fees (2026)

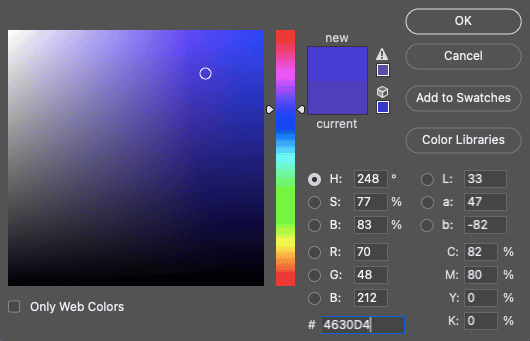

2. Set up print files to match each supplier's specs

A well-designed file can still print poorly if it isn't set up correctly.

Each POD supplier has unique print settings, so it is essential to follow their specific file guidelines.

Use sRGB color mode, 300 DPI resolution, and include a 2-3 mm bleed. Keep key design elements away from the edges.

Treat file setup like a production process, not just a design, to avoid blurry prints and color issues.

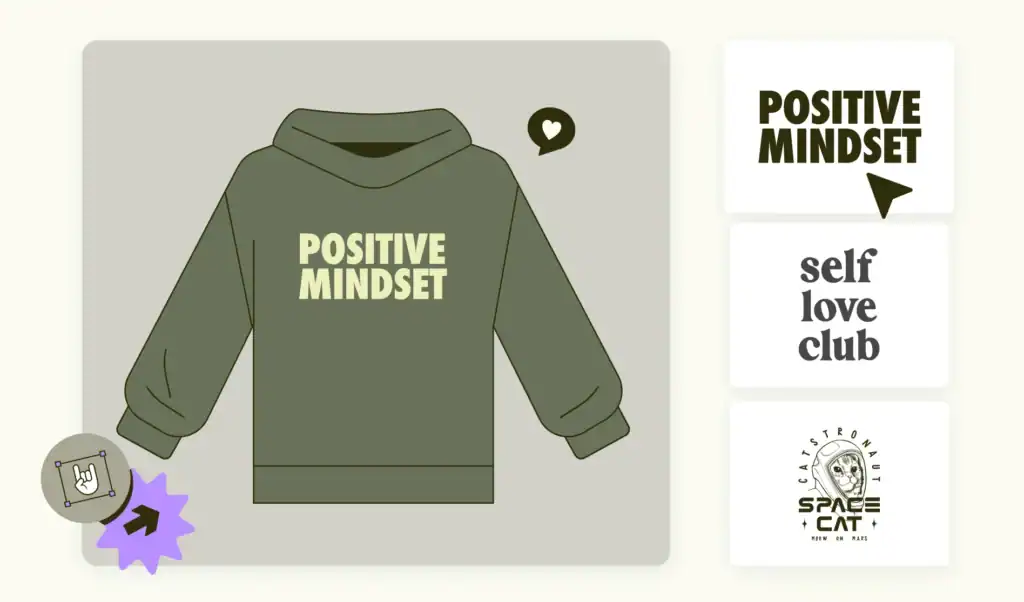

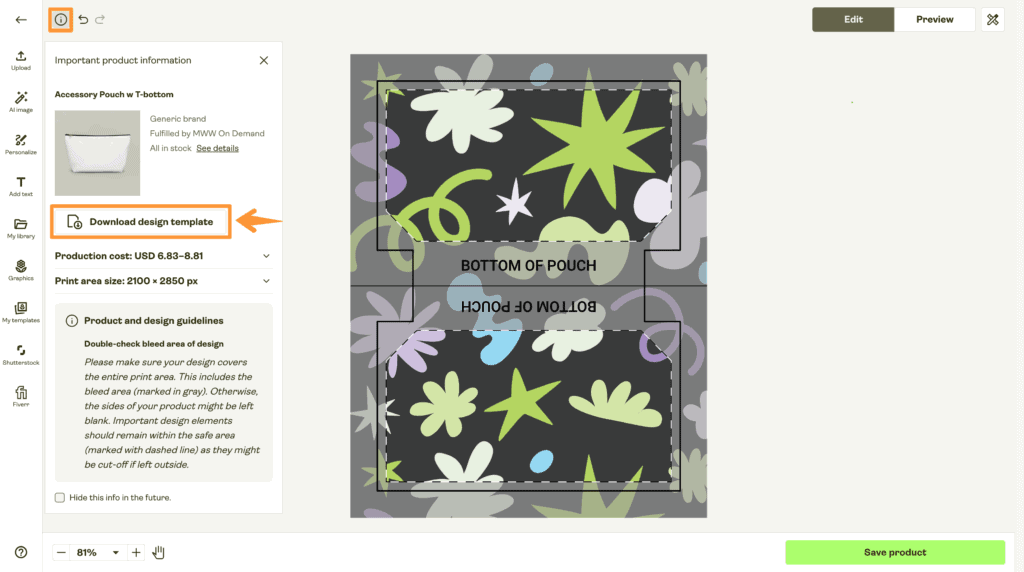

3. Use standard templates to keep designs consistent

Consistent templates help avoid printing mistakes and keep your team on the same page.

Create a template for each product that includes clear safe zones, print areas, and bleed lines. This ensures key design elements won't be cut off or misaligned during production.

Use clear naming and version control, especially when working with freelancers or a team, to ensure consistency and maintainability. One outdated file can result in dozens of incorrect orders.

Printify recommends filling the full print area but keeping important details inside the safe zone. Templates make this easy and repeatable.

4. Always check the print preview before you approve

Mockups might look clean, but they don't catch real-world print problems.

Before sending anything to production, review the print preview carefully. Zoom in, check the alignment, and ensure everything's centered and sized correctly.

For any bestseller, seasonal launch, or influencer collab, order a hard proof and inspect it under natural light.

A hard proof shows you exactly how the final product will look in your customer's hands, and helps catch issues that even a calibrated monitor won't reveal.

It takes a few extra minutes, but it can save you from refunds and bad reviews.

5. Avoid the most common POD design mistakes

Some printing mistakes recur frequently, but they're easy to prevent.

Use high-res images (300 DPI or vector) to avoid blurry prints. Low-res uploads are one of the top reasons for poor quality.

Avoid tiny text, thin lines, or low-contrast designs, especially on dark or textured backgrounds. They often don't print clearly!

Stick to one color space (sRGB is best) and always extend your design into the bleed area. Missing bleed can cause unprinted edges or weird borders.

Learn more: 10 Most Common Dropshipping Mistakes & How to Avoid Them

6. Pay attention to what your customers are saying

Your customers are your best quality control, but only if you're listening.

Even if your files are perfect, things can still go wrong. Think faded prints, wrong sizes, or delayed shipping.

Check your reviews, support emails, and social media at least once a week. Watch for repeat complaints like “blurry print” or “wrong item sent.”

Use automated post-purchase surveys (via Klaviyo, Judge.me, or Loox) to collect product-specific feedback.

Track recurring issues in a shared doc to flag which products or suppliers need attention.

7. Use a “Golden Sample” to keep quality consistent

A golden sample is your go-to standard for how a product should look.

Once you finalize a design, order one perfect print and keep it as your reference. Use it to check future orders, resolve supplier issues, or recalibrate equipment if things start to go off track.

This is essential for bestsellers or high-volume products, where consistency is crucial.

Golden samples are your insurance policy against "quality fade", when long-term suppliers quietly lower their standards to cut costs.

8. Create multi-supplier redundancy for bestsellers

Relying on one supplier might feel easier, but it's a gamble.

If they suddenly have delays, stock issues, or a drop in quality, your top products (and profits) are at risk.

That's why it's smart to set up a backup. For your bestsellers, have at least one other trusted supplier ready to go.

You don't need to double your entire catalog, just cover the top 20% that drive 80% of your sales.

It's how smart stores stay resilient and keep customers happy, rather than just being a safety net.

How to handle quality issues when they happen

Even if your files are perfect and your mockups look sharp, things still go wrong. It's part of running a real POD store.

When it happens, don't wait around, take action fast:

- Offer a refund or replacement right away. Don't stall while you wait for supplier approval. Your customer expects you to fix it, not to pass the blame. (Learn more here about POD returns)

- Ask for customer photos. These help you document the issue when filing a claim with your supplier. A picture of a misaligned print is harder to dispute than a written complaint.

- Track every issue. Use a shared 'Issue Tracker' doc (Google Sheets works fine) and log the product, supplier, date, and what went wrong. Patterns will show up fast.

- Set hard rules. If one supplier causes more than three quality issues in a month, pause new orders. It's easier to switch to your backup than to keep chasing fixes after the damage is done.

Handling issues well won't just save the sale; it'll protect your brand and show customers that you care more than your competition.

Turn this guide into an AI checklist

Click your favorite AI tool below to get a short summary and step-by-step checklist based on this article.Prefer ChatGPT? Open this guide in ChatGPT with a pre-filled prompt (most readers start here).

Summary

Before we go, we've created a quick summary of this article for you, so you can easily remember it:

- Order samples to ensure you know exactly what your customers will receive. No surprises.

- Set up your files based on each supplier's guidelines. They're all a little different.

- Use templates to keep your designs organized and print-ready every time.

- Always check the print preview. It's your last chance to catch mistakes.

- Watch out for common errors, such as low-resolution images, poor contrast, or missing bleed.

- Read your customer feedback regularly. It's full of clues on what to fix.

- Save a golden sample of your bestsellers so you have a clear quality reference.

- Don't rely on one supplier. Have a backup for your top products, just in case.

Conclusion

Quality control in POD isn't just about avoiding returns. It's about earning trust!

Your customer doesn't care who printed the shirt. They only remember where they bought it.

So if the print's off or the colors fade, it's your brand that takes the hit.

That's why quality is more than a “nice to have,” it's the thing that keeps people coming back.

Keep it consistent, stay picky, and your store will stand out in the best way.

Thank you for reading!

Want to learn more about POD?

Ready to move your print on demand store to the next level? Check out the articles below:

- 6 Tips to Diversify Your Print on Demand Store

- 14 Best Unique Print on Demand Products to Sell

- How to Master Quality Control When Dropshipping

- 10 Print on Demand Marketing Strategy Tips (Grow Your Store)

Plus, don't forget to check out our in-depth how to start a print on demand business guide here!